Research PR showcase! Vol.3: Bonds woven with silk engineering

IRCAEB Dept. of Molecular Agriculture, Takuro Niidome

Research PR Showcase Vol.3 will feature the research of Prof. Niidome about

the application of silk as biomaterials.

Prof. Niidome’s research on silk engineering began with an encounter with Prof. Makoto

Sasaki (currently associate professor of the Faculty of Advanced Science

and Technology, Kumamoto University, and CEO of Charlie Lab Inc.). At the

time, Prof. Sasaki was working in a venture to develop a medical device

called “stent” and was seeking to collaborate with Prof. Niidome.

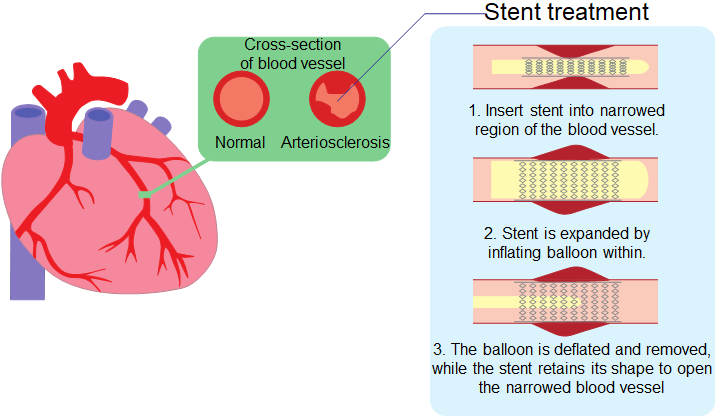

Stents are used in treatments of stenosis such as arteriosclerosis, where

they open up blood vessels that have become narrow. Since stents’ first clinical application in early

1977, suitable materials have been sought out to make stents that can support

blood vessels with twists and turns, with progress continue to be made

today.

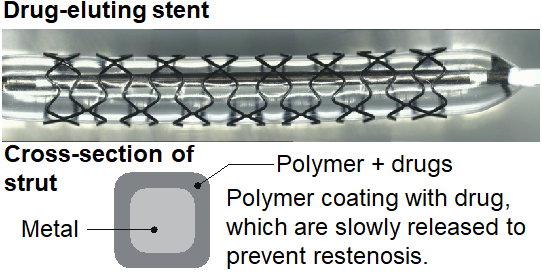

The first-generation stents were made with stainless steel or cobalt-chromium

alloys. However these metals trigger inflammations and cause the blood

vessels to close up again (restenosis). The second-generation stents added a layer of drug-loaded polymer coating

on the metal platform (i.e. drug-eluting stents).

The drugs release from the stents suppresses cell proliferation and effectively prevent restenosis.Nevertheless, since these metal stents

permanently remain in the body, they can still cause blood clots long after

the stent is implanted (late stent thrombosis).

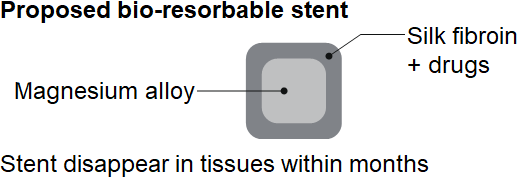

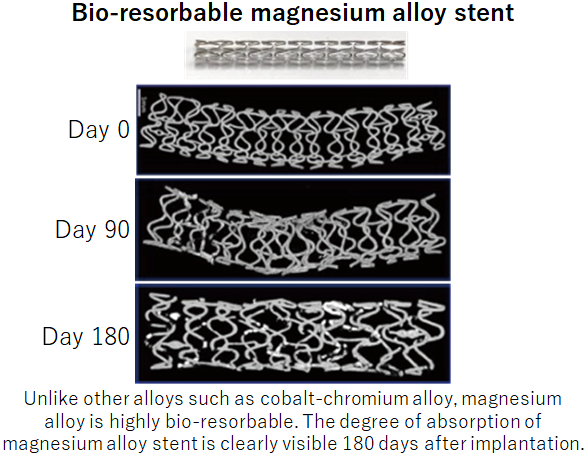

When Prof. Niidome first met Prof. Sasaki, the idea of making stents that

get gradually resorbed by the body and eventually disappear was gaining popularity among the

stent manufacturing industry. These are considered to be the third-generation

stents. At the time, Prof. Niidome and Prof. Sasaki were considering a

combination of the stent platform made of bioresorbable magnesiumalloy and the layer of silk protein coating with high biocompatibility.

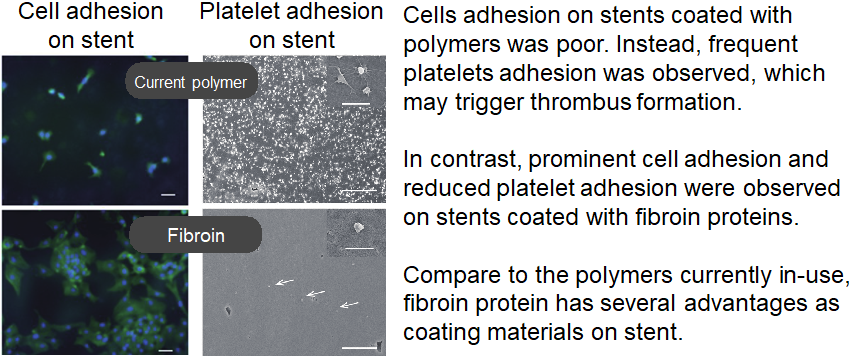

Typical stent-coating materials are hard polymers. Among the many potential

candidate polymers, some release the drugs too fast, while others have

poor biocompatibility. Often compromises must be made to balance these

properties of stent-coating materials. Prof. Niidome’s idea was to test

how feasible is it to coat stents with silk proteins.

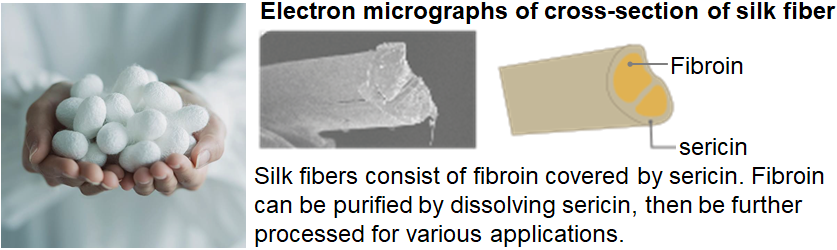

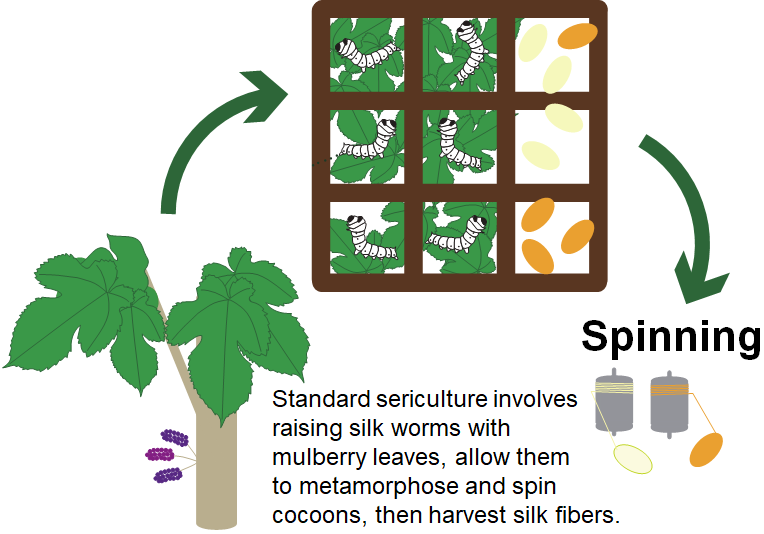

So what are silks made of in the first place, some of you may wonder? Silks

are composed of fibrous animal proteinsfound in silkworm cocoons, with fibroin proteins making up the fiber cores and sericinproteins coat the fiber surfaces. In Prof. Niidome’s research, sericin

is removed and pure fibroin is isolated.

Since we humans are also made primarily of proteins, silk should be highly compatible with the human body. Indeed, since ancient times silk clothes were prized for eliciting little adverse response on the body, making it a promising candidate material for medical applications. In addition, researchers of the National Institute of Sericultural and Entomological Science (currently National Institute of Agrobiological Sciences) have successfully developed silkworm transgenic technologies in the year 2000. It is now possible to genetically alter the physical properties of fibroin to make better products. These are incentives have thus spurred the progress of silk engineering in Prof. Niidome’s research.

The silk-engineering technology finally starts to take shape, after many

trials-and-errors. Firstly, stent-coating synthetic polymer can easily

be manufactured in factories, but proteins still must be synthesized by

silkworms. Both silkworms and their natural food source mulberry plants

are living organisms, and silkworms must be kept for long enough to spin cocoons before silks

can be harvested. Therefore silkworm-rearing and cocoon-harvests remain

difficult to be carried out in traditional factory settings.

The next challenge lies in the fact that medical device to be placed within

human bodies must be sterile. In another word, simply fabricating fibroin-coated stents will not suffice,

as facilities that prepare the silks must also be aseptic. Unfortunately,

the necessity of such facilities was overlooked during the outset of the

research project.

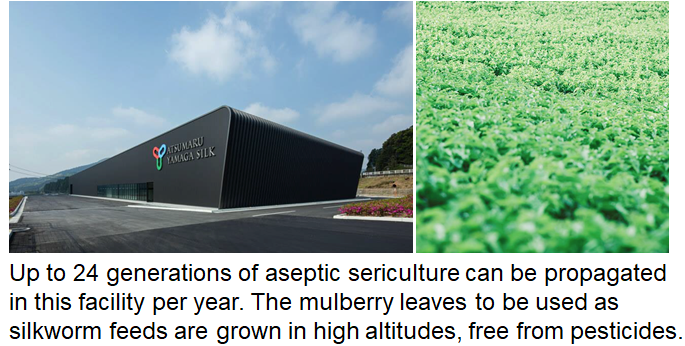

With a stroke of luck, at the time Atsumaru Holdings Co. Ltd., a company for job information based in Kumamoto happened to be converting defunct school buildings into aseptic silk production factories in Yamaga city. Even though Prof. Niidome was initially not affiliated with the project, after extensive negotiation a collaboration with the Yamaga silk factory was established. A truly fortuitous turn of event indeed! Starting from 2017, Atsumaru Yamaga Silk Co. Ltd. began year-round industry-scale aseptic sericulture operations, while Prof. Niidome and Prof. Sasaki work on the applications of these sterile silks. The Niidome laboratory now studies the utilities of fibroin as biomaterials, as well as developing novel silk applications in the Atsumaru New Silk Sericulture Joint Research laboratory, donated by Atsumaru Holdings Co. Ltd. Meanwhile, the Kumamoto University-based business venture Charlie Lab Inc., lead by Prof. Sasaki, also contributes to the collaborative research.

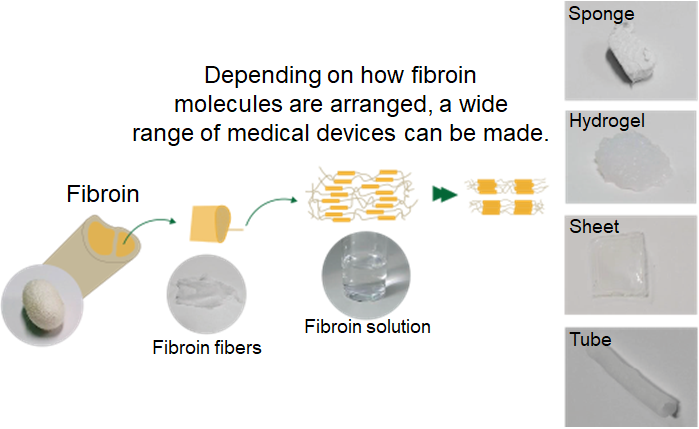

Now that the research material source has been secured, it is possible

to extract fibroin from silkworm cocoons in powder, liquid or gel forms.

Starting with these materials, fibroin can undergo various modifications

to develop new functions.

It’s been about 10 years since Prof. Niidome first met Prof. Sasaki. It

has been suggested that the layer of fibroin coating has the effects of

suppressing the corrosion of magnesium alloy and controlling the drug release.

Furthermore, these stents have been shown to be highly compatible with blood vessel cells, while showing low affinity toward platelets. With the robustness of the basic technologies confirmed, Prof. Niidome’s

stent research can now move toward the practical application phase.

Fibroin made by aseptic silkworms holds great potentials as raw materials to manufacture medical device, due to its low rate of organ rejection. The development of scaffolding for wound regeneration, anti-adhesion cushioning and hemostatic agents using engineered silk proteins are currently under way. Somehow, silkworms have become the bond that connects agriculture and medicine. Next, Prof. Niidome would like to further expand this bond by exploring the applications of silk proteins in the fishery industry of Kumamoto.